Embarking on a digital transformation in supply chain is a challenging journey. It is an expensive, time consuming and labor intensive process. However, once you make the transition to a modern, robust, flexible and efficient ERP system, you will realize the benefits are far higher than the ones provided by age-old manual processes.

As the world has seen in the past year, supply chain shocks are real and are here to stay. From the semiconductor supply shock to the container shortage – these shocks can take the form of either material shortage or capacity shortage. In the worst case – it could be a combination of the two. Because supply chains are so central to a business, any fluctuation can cause significant changes to both revenue and profitability.

Companies that have survived, or even thrived in such turbulent times are the ones that have taken an aggressive and deliberate approach to radically transform the management of their supply chains. Leaders in such companies have embraced digital solutions across a wide range of functions. These solutions range from the ones that provide demand forecasting based on dynamic consumer sentiments and changing weather patterns to always-on visibility on material movement across the supply chain. However, there is always a constant and that is the central ERP application that brings it all together.

In this article we share 4 key areas where ERP solutions play vital role in the digital transformation in supply chain.

Demand planning and forecasting

Forecast accuracy is one of the most important key performance indicators (KPI) in industries that follow a “make-to-stock” replenishment strategy. This KPI is a lagging indicator that tells businesses about how accurately they were able to predict demand by comparing the prior forecasts with actual sales.

Businesses use several methods to forecast demand. The majority of these methods utilize historical sales as important for predicting forecast demands. As the ERP application is the custodian of past sales and delivery data, it should have a built-in capabilities that allow planners to use complex statistical methods to generate forecasts. A modern ERP that supports the digital transformation in supply chain, should enable supply planners to generate multiple versions of demand forecasts for each sales territory.

The ERP should provide extensive integration facilities for demand planners to use external data from sources as diverse as social media sentiment analyses to climatic and weather patterns to identify trends in demands. Planners should be able to add promotional campaigns that the marketing department plans to run to generate demand for new or existing products. They then reach a consensus on the final forecast figures with sales territory owners, the marketing, the operations, and the finance team during periodic S&OP meetings and approve the forecast figures that drive the operational planning and production and procurement processes.

Collaboration with the business network

Companies do not exist in a vacuum. They have trading partners in customers, suppliers or vendors, and other stakeholders that play a critical part in ensuring the overall success of the business. For business leaders, collaborating with such partners, in the day-to-day operations, can make a dramatic difference to the efficiency and profitability of their organizations.

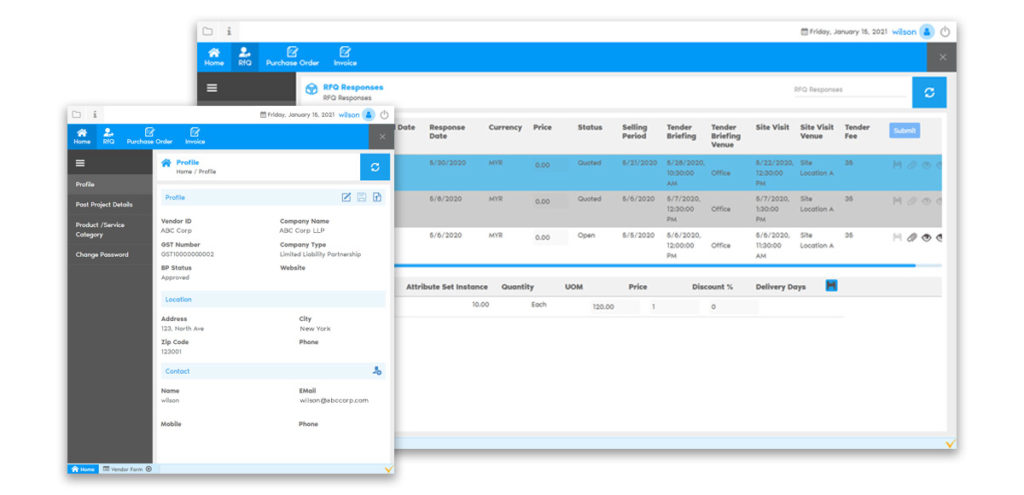

The digital transformation in supply chain, should be supported by a modern ERP software that is at the forefront of enabling this collaboration. For example, Onfinity ERP provides a comprehensive vendor portal for their suppliers and vendors to directly participate in the procurement process.

From responding to Requests for Quotations (RFQs) or tender documents to the provisioning of Bills of Quantities (BOQs) and material specifications, vendors are able to seamlessly provide context-rich information for procurement teams to accelerate decision making. Similarly, ERP applications such as Onfinity provide customer collaboration portals that allow customers to send sales or service-related information.

These means of collaboration, built directly within the core ERP application translate into substantial value for businesses! Not only does it save time, but such a collaborative platform also improves the quality and velocity of information exchange and provides a legitimate single source of truth for all enterprise data. Leaders that want to transform their supply chain into a more resilient, agile one, should look for an ERP application, as a central digital core, with strong collaboration capabilities.

Command center – supply chain visibility

An efficient supply chain is one that facilitates the frictionless flow of material, value, and information. For a very long, the “information” element of the supply chain was neglected by businesses and solution providers. With modern ERP software solutions such as Onfinity, supply chain visibility becomes a reality. With these capabilities, businesses can plan for possible disruptions in their receivables or deliveries or react to sudden changes in production or transportation capacity availability.

For instance, logistics execution for outbound deliveries is an important part of efficiently utilizing available stock, handling resources, and coordinating all steps from creating deliveries to invoice generation. With an ERP such as Onfinity, these processes form a part of the standard product offering. More importantly, Onfinity provides customers with the possibility to integrate the core ERP with other supply chain visibility solutions via a robust integration layer via web services.

Automation and digital transformation in supply chain

Rapid advances in technologies such as Optical Character Recognition (OCR) have made it easier and very cost-effective to automate a variety of repetitive tasks. Supply chain execution is an area that has a high concentration of manual repetitive tasks. ERP applications can play a central role in the digitalization of these processes that would yield non-linear efficiency gains to organizations that are able to identify the right areas to transform.

Executives considering digital transformation in their supply chain operations should look for an ERP solution with inbuilt enterprise-grade document management system that has advanced OCR capabilities. With this, customers can extract information from structured and unstructured documents to populate pre-defined information in the ERP application, eliminating hours of manual data entry. Several customers using Onfinity have realized efficiency and accuracy gains in processes such as accounts payable management, vendor invoice management, document workflow automation.

Another area of automation is maintenance of fixed assets. With Internet of Things (IoT) technologies gaining widespread usage, companies are using them to attach such IoTs to machinery and other assets to monitor their conditions on a continuous basis. With such an approach, the manual task of maintenance inspection is dramatically reduced thereby allowing companies run their manufacturing cycles more reliably. Onfinity provides a comprehensive library of web services for companies to integrate various IoT based solutions with the core ERP.

The bottom line

What was earlier considered to be just a transaction recording application, ERP systems have transformed to serve as the “single source of truth” in the enterprise. From finance to supply chain management, the ERP application touches every aspect of the business. It is therefore important that leaders look at the ERP as integral to any digital transformation initiative in supply chain.

Transiting to a modern digital core, helps organizations achieve operational efficiency and enhances their financial performance enabled by a strong enterprise level ERP system, like the one offered by Onfinity