Key operational benefits

Automate warehouse operations

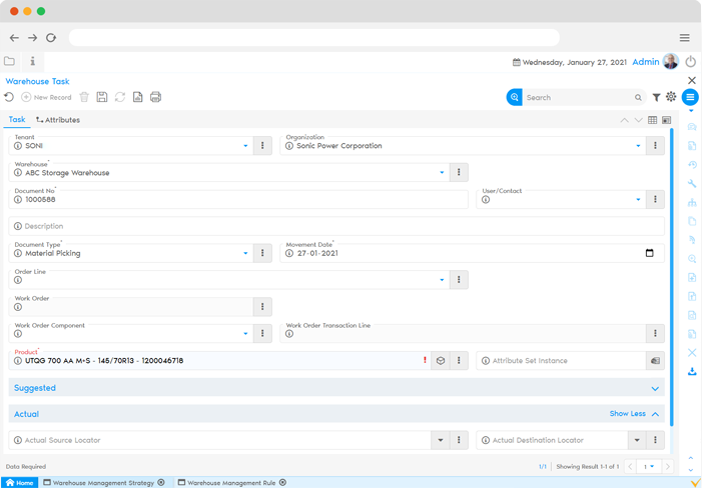

Automatically generate warehouse tasks lists based on user-defined strategies for picking, put-away, optimization and cross-docking activities. Integration with SCADA systems ensures seamless communication with warehouse material handling equipment.

Tightly integrated with other ERP modules

Handle operations from various departments with one powerful software solution. The data in your warehouse management system is always connected with other Onfinity modules like CRM, Order and Purchase Management Financials, BI, and more.

Use mobile devices and latest technology

Onfinity WMS is easily integrated with automatic identification and data capture technology such as barcodes, RFID scanners, and output devices such as printers. The WMS is accessible from any mobile device, anywhere.

Increase warehouse productivity

Eliminate unnecessary administrative activities and focus on productivity. Reduce warehouse labor overhead and handle the increased workload with fewer warehouse resources.

Multiple warehouses, one robust system

Setup multiple warehouses, zones and locators, manage inbound, outbound and optimization strategies on one common platform.

Ensure accuracy, reduce customer complaints

Reduce errors in order fulfillment to a minimum! Onfinity WMS helps you pick the correct products with clear instructions from the warehouse management system.

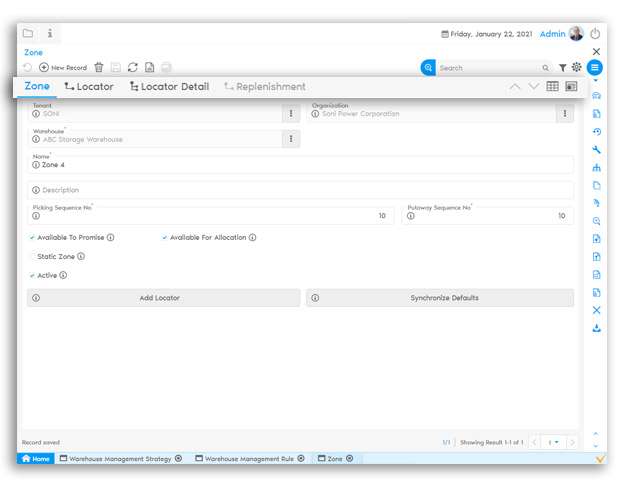

Configurable Warehouse Design

Setup custom warehouse storage configurations using multiple zone definitions and multiple locator coordinates such as aisles, bays, levels, positions, and bins. Utilize the ‘volumetric locator’ definition feature to accommodate odd-sized loads or consolidated lots. Reduce picking/putting-away cycle time using storage optimization strategies.

High-volume Order Fulfilment

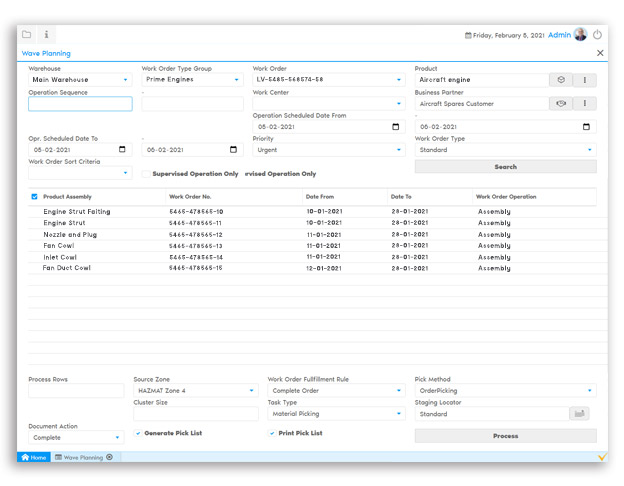

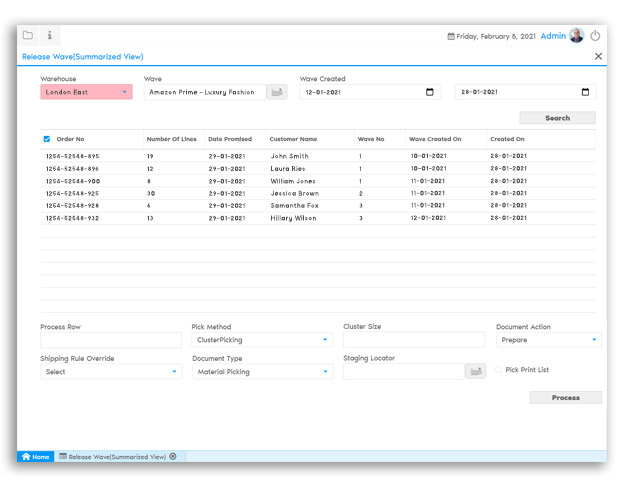

Fulfill tens of thousands of orders in large retail fulfillment centers by executing multiple waves, based on multiple wave-sort criteria and strategies, unique to your warehouse storage and handling configuration.

The Onfinity Warehouse Management Solution allows you to create, plan and release waves in one single step or in multiple steps. Schedule and execute the entire wave planning process defining specifically at what intervals they need to run and based on what specific criteria. Generate warehouse tasks based on wave-runs and communicate the tasks to other equipment control systems or SCADA.

Enhance scalability with automated warehouse operations

Use automation to handle high-volume transactions seamlessly and orchestrate inbound and outbound processing. Set up a full material flow system to facilitate automated storage and retrieval functions, inventory storage location suggestions as well as warehouse space utilization and optimization.

By automating some of the processes in your warehouse you will eliminate redundant manual processes and optimize inventory tracking, cross-docking, picking and putting-away operations, multichannel fulfillment, distribution operations, and more.

Get more in depth understanding of your warehouse operations

Explore all features, and learn the real power of Onfinity Warehouse Management module

Inventory control

Maximize profit from the least amount of inventory investment without intruding upon customer satisfaction levels.

Wave planning

Onfinity Warehouse Management System is flexible and user configurable, and helps you build waves of orders to be picked in the warehouse.

Pack and ship

Automatically generate shipment documents, consolidate shipments, reduce errors due packing and speed up the shipment process.

Warehouse planning

Set a warehouse management strategy and configure the structure of your warehouses and locations in order to optimize your resources, better manage storage space, and speed up the movement of goods within the warehouse or from one to another warehouse location.

Warehousing operations

Support and automate warehouse operations with cutting-edge warehouse management software.

Inbound operations

Set predefined directed put-away rules in order to decrease the time needed to receive goods either from external source or from another warehouse location.

Outbound operations

Set predefined directed picking rules, and choose picking method to better manage outbound operations. Have a centralized monitoring of all active tasks in your warehouse.

Warehouse reporting

Choose from a long list of ready made warehouse reports to have a real time overview of your stock levels, storage details, worker performance and much more. Onfinity WMS is tightly integrated with business intelligence platform and lets you create your own custom reports.

Distribution management

Align your distribution strategy to your business strategy with a host of features that generate success.

Talk to our consultants

Contact us today to get an accurate cost-benefit analysis between Onfinity and your current ERP solution.

REQUEST FREE TCO ANALYSIS