Key operational benefits

Configurable Internal Logistics

Manage multiple warehouses, maintain unique warehouse storage configurations, material policies, replenishment strategies and ensure maximum volumetric utilization of your warehouse space.

Technology-Driven

Complete integration with IoT! Integrated with RFID and barcode scanners, consolidated with a comprehensive WMS, and accessible on mobile devices. Control, monitor, and optimize your inventory using data-driven insights.

Powerful Reporting

Create custom reports in a matter of minutes using the powerful embedded business intelligence and analytics tool. Data-driven insights and story-boards provide a reliable decision-support basis.

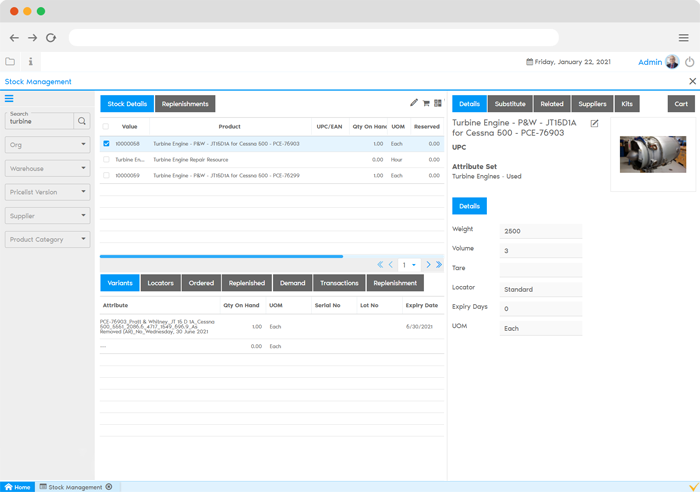

Accurate Stock Information

Comprehensive material management transactions to ensure accurate stock management and visibility across warehouses, products, product-variants, and SKUs. Data-driven forecasts assist in replenishment planning, ensure optimum inventory levels and reduce inventory absorption costs.

Fully Integrated

Our Inventory Management software is fully integrated with Onfinity ERP and CRM solution and all related modules such as, sales management, order management, manufacturing, purchasing, point of sale, to provide a seamless user experience.

End-To-End Logistics Solution

Product categories and variants, product BoM, multiple UoM, batch and serial management, packaging, packing and consolidation, inbound, outbound and stock optimization transactions, material movement policies, replenishment strategies, and much more extensively integrated with Onfinity Warehouse Management System.

Optimize your inventory

Optimize your inventory levels with fully automated replenishment, manage material movements, purchase-to-order, and eliminate pilferage. Improve demand planning and decrease safety stock levels to cut costs, manage internal use and physical inventory changes, manage inventory valuation, maintain accurate inventory in order to schedule purchases and production, and much more.

Configurable rules

With Onfinity Inventory Management module configure replenishment rules and alerts to avoid out-of-stock situations and consequent loss of sales. Moreover, set up optimum stock levels and purchasing rules to avoid locking-in money on excess stock.

REQUEST FREE DEMO

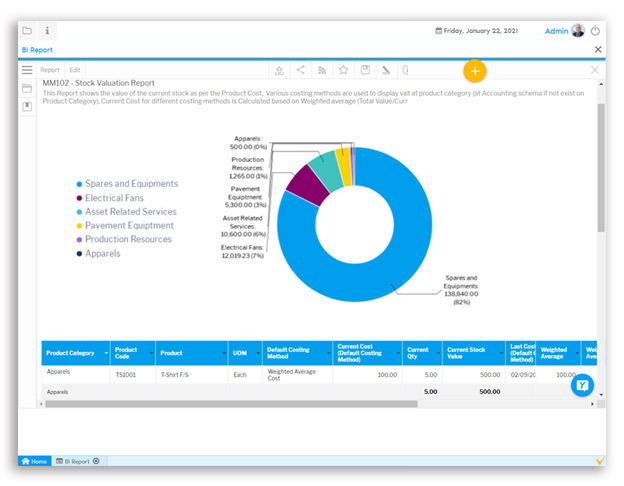

Track your storage value using various stock valuation methods

Onfinity Inventory Management module lets you choose your preferred stock valuation method, whether it is a valuation based on the product, organization, LOT, or consignment, etc.

Choose multiple stock valuation methods at the same time and enable automatic valuation and posting into the accounts.

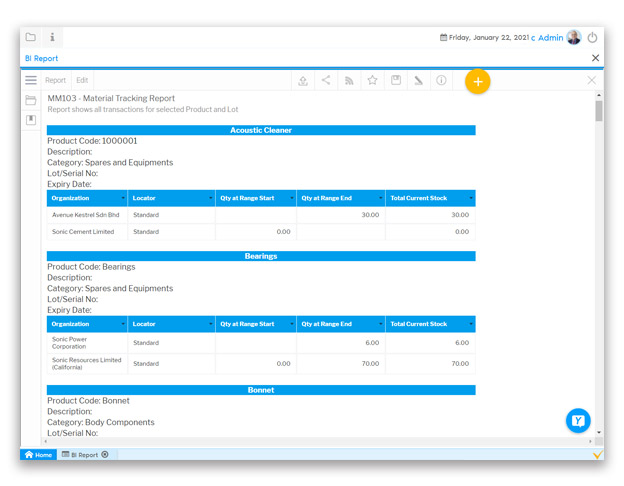

Ensure total traceability

Track every stock movement from purchase to warehouse bin, to sales order. Trace items by batches, serial numbers, lots and expiry dates from anywhere in your supply chain. Sell the old batches first by using automatic FIFO/FEFO and ensure goods are consistently available at the right time and place. The tightly integrated Order Management module ensures that the right product is delivered to the customer, on time.

Get more in depth understanding of your stock

Explore all features, and learn the real power of Onfinity Inventory Management module

Warehouse and Locators

Define your warehouse and replenishment structure and rules. Manage complex warehouse operations and automate pick-up and put-away.

Automatic Replenishment

Define your replenishment rules and set workflows to schedule and automate common inventory tasks such as automatically triggering purchase orders.

Purchase or Requisitions

Enjoy complete automation of your purchases or requisitions. The system takes decisions based on rules whether to trigger a purchase or send requisition to a connected warehouse.

Product Management

Manage every aspect of the product you can think of. From product attributes, categorization and hierarchy to expiry dates, multiple barcodes, UOMs, lifecycle handling, warranty management, etc.

Handheld Support

Manage all inventory operations using handheld devices. Physical counting is supported by mobile tools and devices.

UOM conversion

Manage and transact with multiple SKUs and barcodes for a single product, as well as set different pricing depending on the UOM.

Barcodes

Onfinity Inventory Management module supports all types of barcodes. Moreover thy system enables you to set multiple barcodes for each SKU / product.

Material Requirement Planning

Maintain discrete products, accurate bill-of-material, accurate inventory status and take advantage of stable lead times to greatly optimize your procurement, warehousing and manufacturing activities.

Materials Management

Set up material management structure and create your very own storage and supply structure across warehouse and locators. Simplify re-ordering process and reduce cost of purchases.

POPULAR INTEGRATIONS

-

-

Talk to our consultants

Contact us today to get an accurate cost-benefit analysis between Onfinity and your current ERP solution.

REQUEST FREE TCO ANALYSIS